How does Energy Efficient Glazing work?

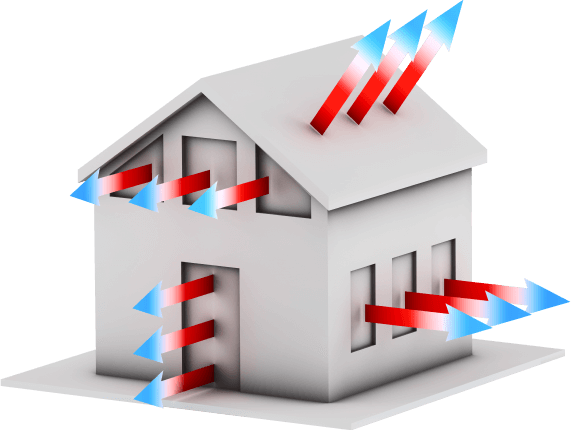

The largest portion of any window is the glass surface. Therefore, it has the greatest potential for both loss and savings. Historically, windows featured only a single pane of glass and energy could easily move from one side to the other. The area near windows was usually cold compared to the other side of the room and the panes themselves were cold to the touch.

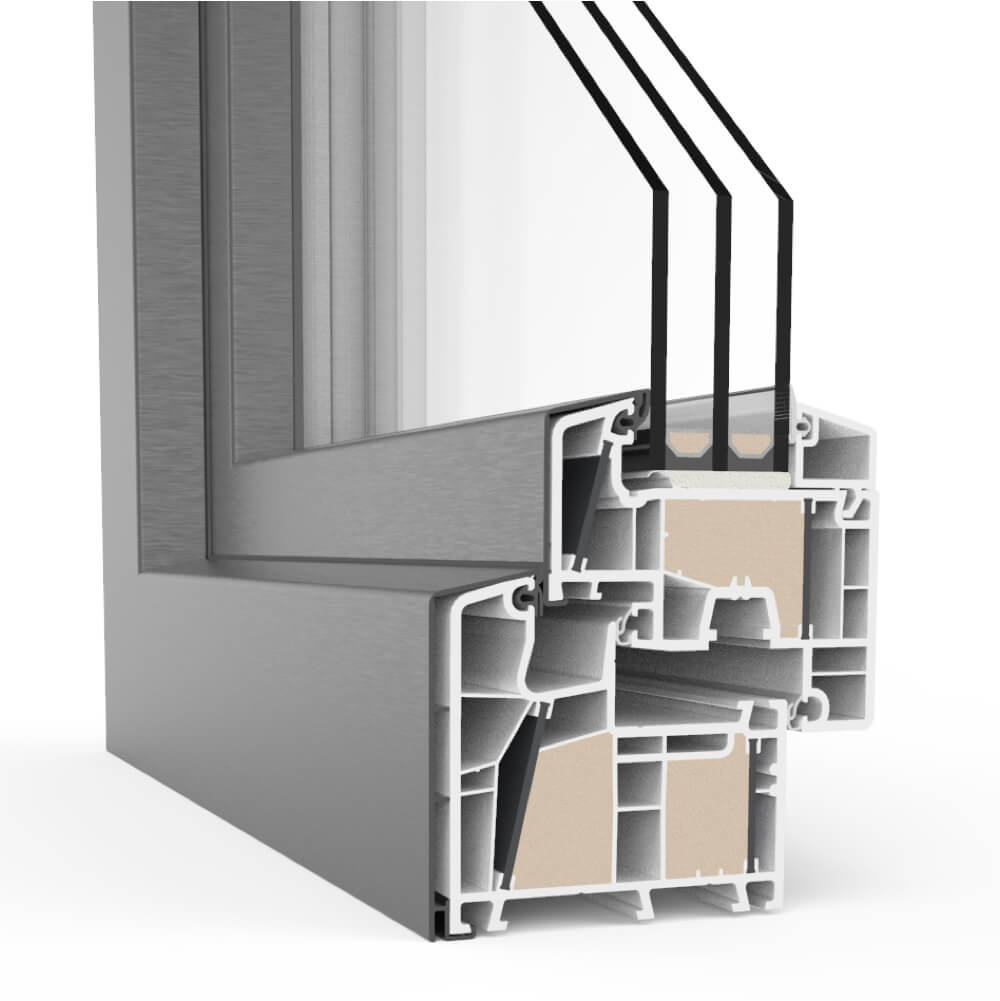

Then came double glazing and today triple glazing. Using multiple panes of glass creates an insulating gap, often filled with an inert gas such as argon. The additional panes and air gaps serve to trap heat inside and prevent energy from moving from the inside to the outside.

Gas fillings such as argon, krypton and xenon are less conductive than air, meaning it is even harder for heat to move through it.

Double-glazed windows may be sufficient for mild climates but triple-glazed is increasingly the norm.

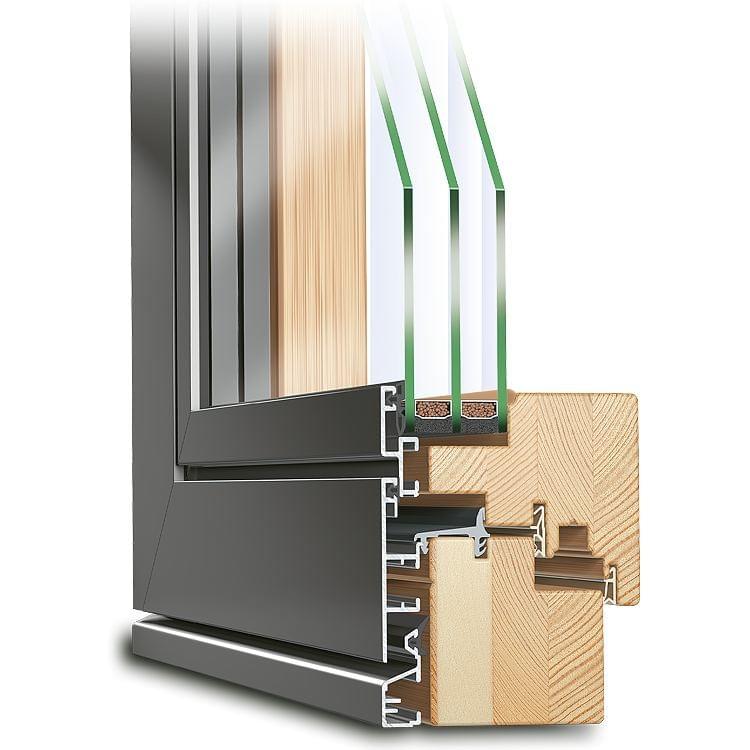

Finally, sealing the insulated glass units with warm edge spacers is critical to ensure that the gas does not escape and no moisture enters. The spacer is also made of thermally optimised material which helps prevent energy from moving from pane to pane via the spacer.

Low-E Coatings

In addition to the glass itself, special coatings can be added to influence the amount of infrared radiation (i.e. heat) allowed to pass through the glass. This is known as low-e or low-emissivity.

In colder climates, it is often applied to the interior so that heat is deflected back into the home whereas in warm areas, the opposite is done to minimize internal heat gain.

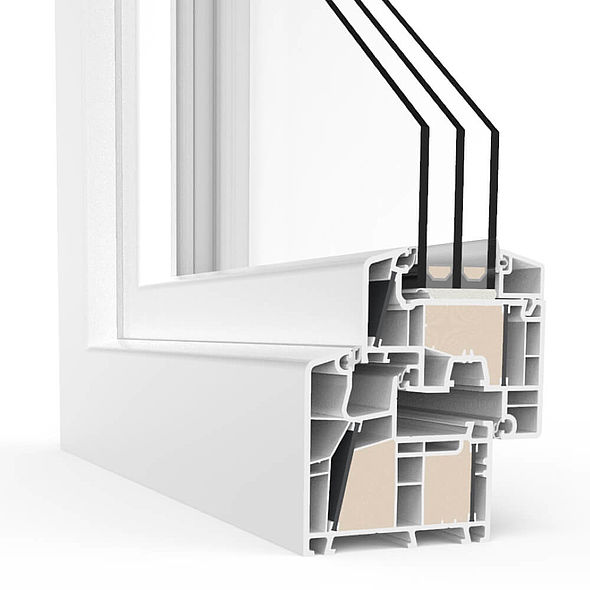

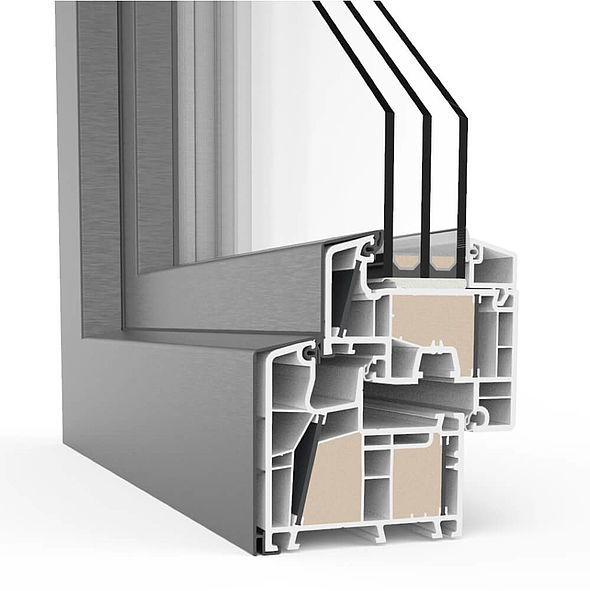

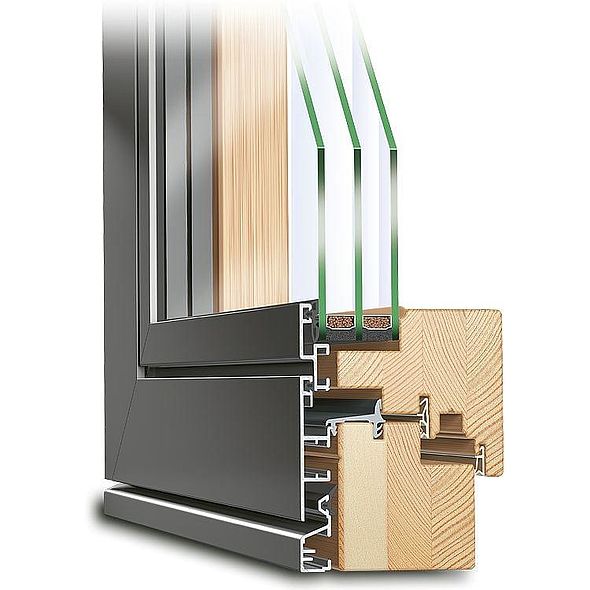

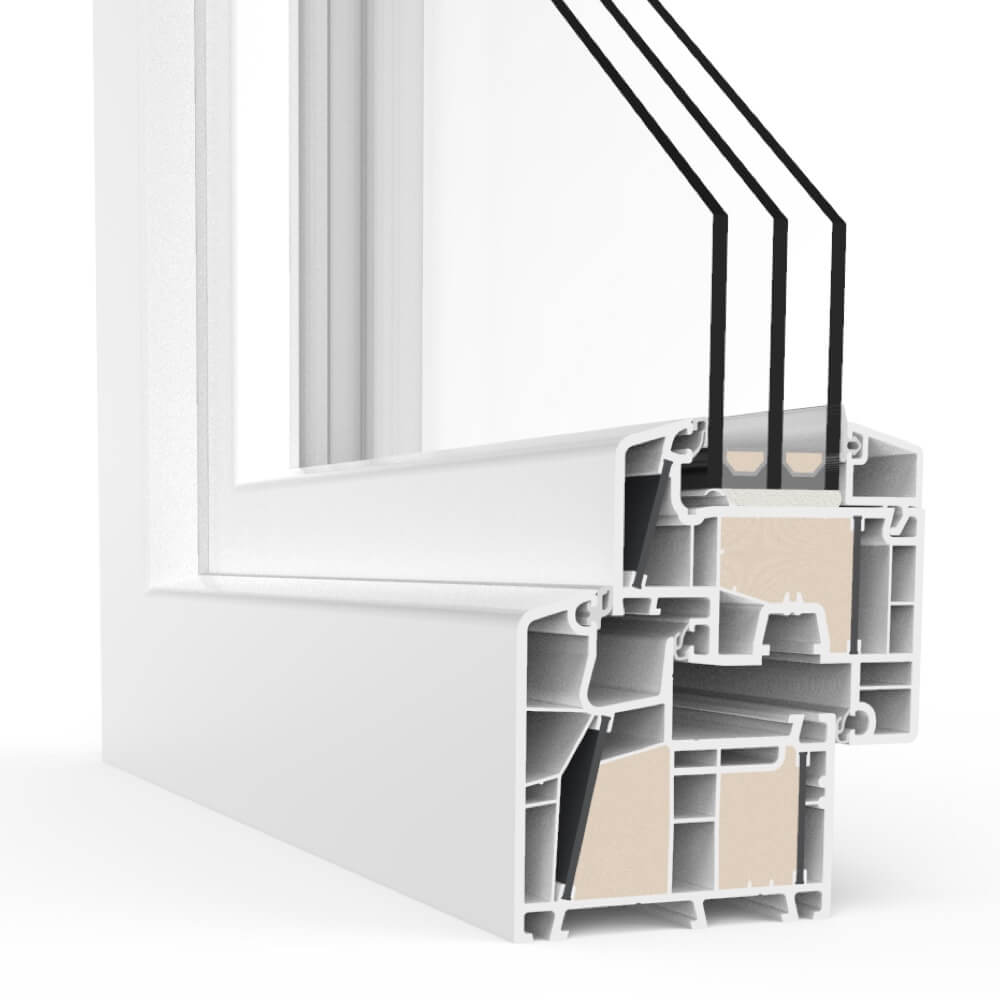

![[Translate to English:] Energiespar Faktor Material und Profil [Translate to English:] Energiespar Faktor Material und Profil](/sites/de/files/img/fenster/energiesparfenster/material-profil.jpg)

![[Translate to English:] Energiespar Faktor Verglasung [Translate to English:] Energiespar Faktor Verglasung](/sites/de/files/img/fenster/energiesparfenster/verglasung.jpg)

![[Translate to English:] Energiespar Faktor Thermischer Randverbund [Translate to English:] Energiespar Faktor Thermischer Randverbund](/sites/de/files/img/fenster/energiesparfenster/thermischer-randverbund.jpg)